PROBLEM

A group project to evaluate the ergonomic suitability of an existing product with significant existence of ergonomic evaluation available as well as the ability to build a representative model in SAMMIE/NX11.

SOLUTION

Modeled, rendered and evaluated a Europa 2000VS Turret Milling Machine using a real life milling machine to accurately dimension the CAD model. Imported into SAMMIE ltd. to ergonomically evaluate the model against a self made design specification, using information from academic publications, British standards and manufacturers. Rendered the model in Keyshot 9, using advanced material graphs. Further Design Work was completed as a result of the findings to develop a more ergonomically suitable milling machine.

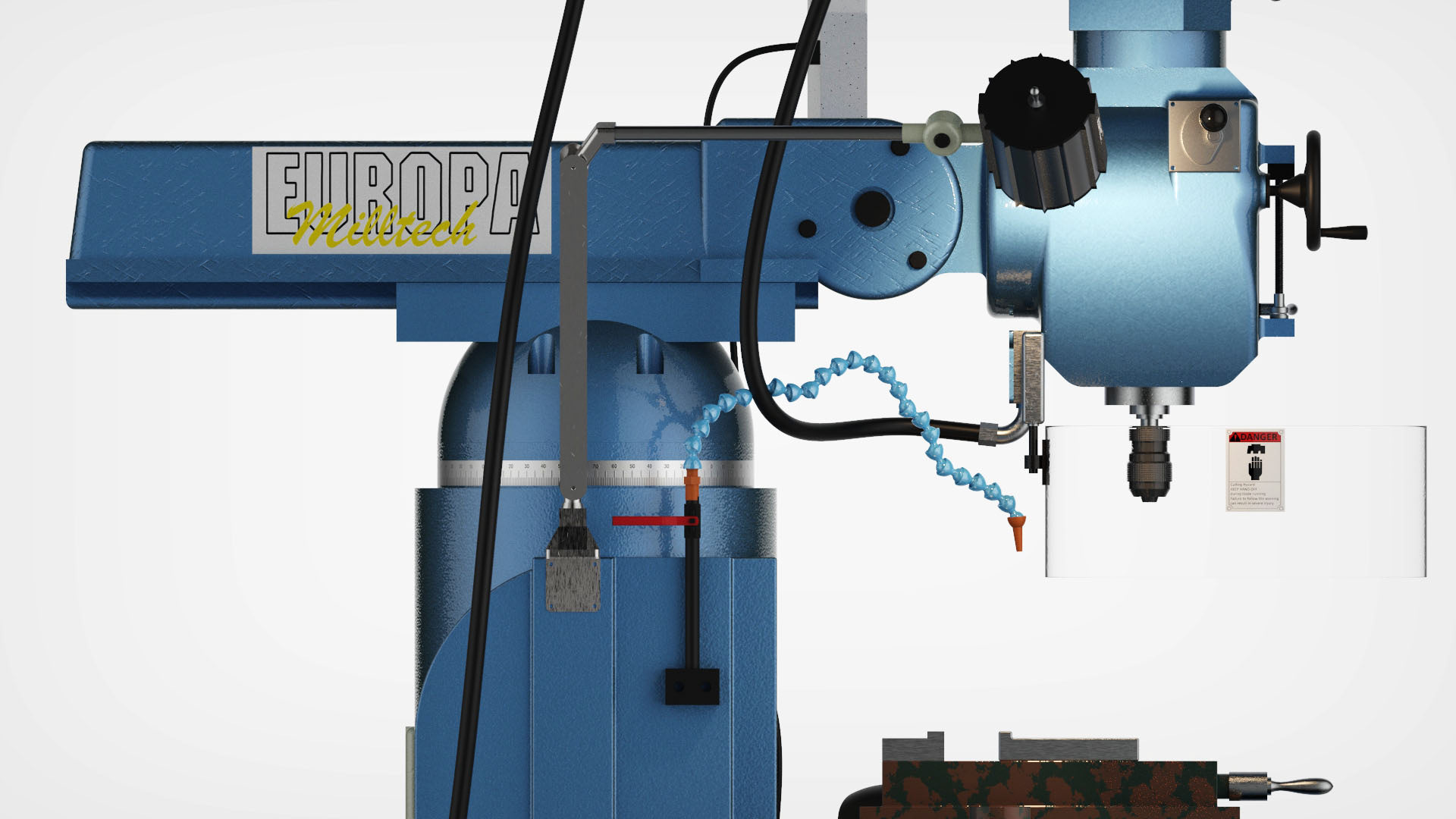

Final Milling Machine Product Visualisation

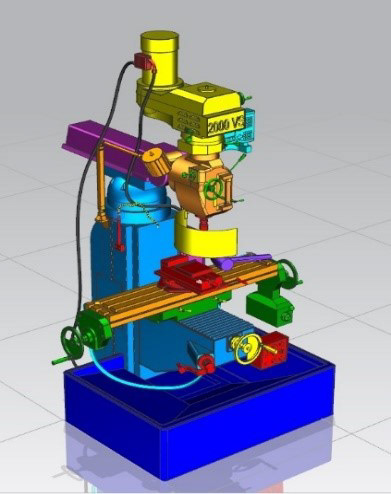

CAD MODELLING

Physical dimensions of the manual milling machine were recorded using a range of measurement equipment and the use of photograph comparisons. The result was a dimensionally accurate full-scale model of Europa 2000VS Turret Milling Machine.

ERGONOMIC EVALUATION

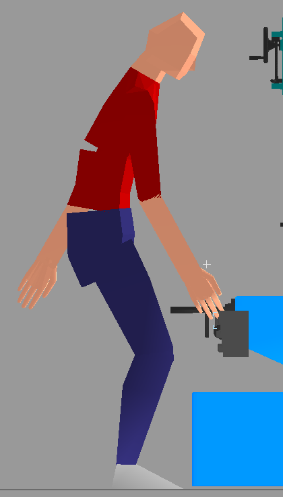

The model has been transferred from to SAMMIE CAD Ltd. to allow for an anthropometric evaluation of the machinery’s components positions in relation to the physical limitations of the expected operators.

95th percentile male was initially unable to reach the front wheel by 65mm. To reach, the model was extended to the physical limits for the thighs and thoracic spine region.

40th percentile female, spindle control out of reach by 266mm

80th percentile female was unable to reach the light box

For the 95th percentile male, it was required of them to bend their lower leg to 69°

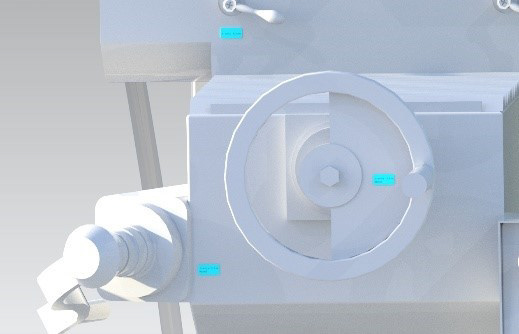

DESIGN WORK

When considering design modifications, we thought about our own experiences using the milling machine, as well as using the data found from our ergonomic evaluation.

Mirror to help see from all angles

Labels to ensure turning in correct axis

Moved to front, less strain on back

PRODUCT VISULISATIONS

Using Keyshot 9 advanced material graphs and lighting to render the Europa 2000VS Milling machine.